Hello crocheters and knitters! So you passed your first quiz, did you? I hope you studied hard and tucked away some facts about the history of knitting; you never know when you'll need to know something! Great work, my friends. Now it's time to move on to your second lesson: chemistry.

Chemistry?? What does chemistry have to do with yarn? Believe it or not, chemical reactions are behind one of the most important considerations you'll make when you start out any sort of project: color.

We know that, broadly, yarns can be put in three categories: protein fiber (like wool and other animal-sourced fibers), plant fiber, and synthetic fiber. But did you know that each of these fibers have to be dyed differently? All protein fibers, like wool and silk, are colored with acid dye. Acid dye uses a combination of hot water and a mild acid like white vinegar to set color in the fiber. Plant fibers are dyed with fiber reactive dye, which bonds with cellulose to create the color you want. It needs to be heated in lukewarm water to work. Synthetic fibers are trickier - these include acrylic, nylon, and polyester yarns, and use varying kinds of composite dye.

Nylon, rayon, and other synthetic fibers are made through especially cool chemical reactions. Check out this video to see how chemists create nylon in the lab!

On an industrial scale, this same reaction is created at very high temperatures to make liquid nylon. At this stage, they can add the dye to the entire batch, and then cool and stretch the polymer into yarn or thread.

Machine dyeing is also very common, and guarantees consistent colors across large dye lots. Larger companies such as Berroco, Rowan, and Shibui all use machine dyeing for many of their products. Machine dyeing with composite dyes is also common for synthetic fiber yarns. Here's one way that works:

In a nutshell, the hanks are lined up on big rollers to keep the yarn moving, and rinsed, then bleached in hot water. At this point, the hanks can be moved to the dye chamber, where different parts of the yarn can be dyed separately. Each color needs to be dyed for a set amount of time and then rinsed before moving on to the next color, so this process can take a lot of time for variegated yarns! After all the dyeing and rinsing, the hanks are placed in a large extractor, which spins the yarns at high speed until they're dry and ready to be packaged.

We love machine-dyed yarns, because the color is so consistent, but we also love the subtle changes in hand-dyed hanks too! Many of the yarns we stock here at Jimmy Beans Wool are hand-dyed in small batches. Madelinetosh is one dyer who does this, and this week some of their yarns are on sale! The manufacturers also have awesome Instagram accounts where they share their dyeing process and their colors. Below, Madtosh is using onion skins to create a natural acid dye.

Jimmy (aka Laura) took a trip to visit Madelinetosh and learned to dye yarns with the experts. Here she is dyeing two different (and original!) colorways of Tosh Merino Light!

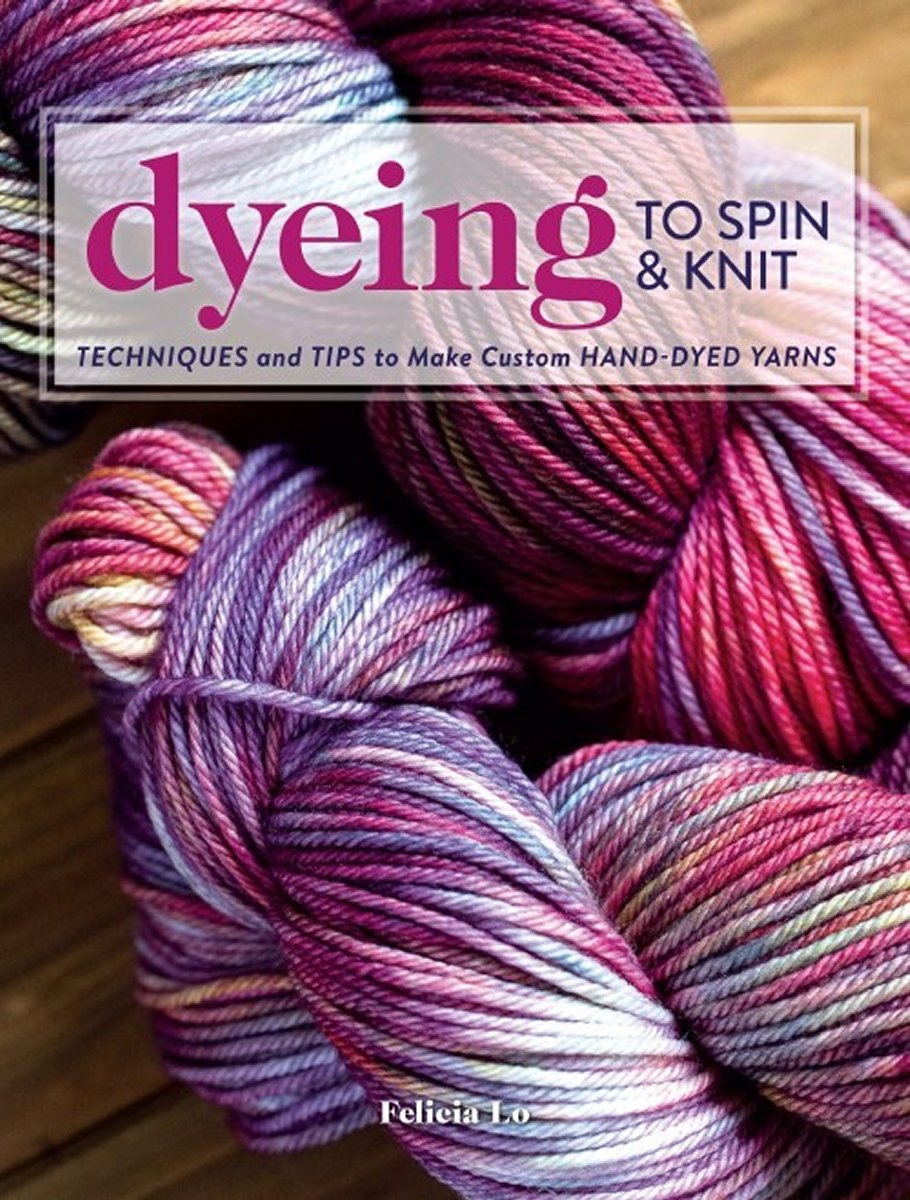

Got the dyeing bug? You can buy plain yarn and start dyeing at home. Check out these great articles on acid dye and fiber reactive dye from Dharma Trading Co to get started, or take a look at this book all about dyeing your yarns.

Got the dyeing bug? You can buy plain yarn and start dyeing at home. Check out these great articles on acid dye and fiber reactive dye from Dharma Trading Co to get started, or take a look at this book all about dyeing your yarns.

Looking for undyed yarns? Our powerful search tool lets you shop for yarns by dye method, so you can find kettle dyed, hand painted, machine dyed, and many others at the click of a button.

Have you ever dyed your own yarn? How did it turn out? What kind of chemistry did you use to dye it? Let us know in the comments!